Rebar Cutting

Line Model: SLV40 / SLV45

Bar Receiving Pedestal Integrated with a Roller Conveyor, Bars to Process Are Dropped-In

Rollers Help the Bar to Progress Smooth with Minimal Effort Pedestal Length 12m – Maximum

Weight Capable 4T

WE ARE OPEN AND FUNCTIONING! WE HAVE STOCKS OF SEVERAL MODELS TO MAKE IMMEDIATE DOMESTIC DISPATCHES AND OVERSEAS SHIPMENTS. PLEASE CONTACT US FOR A QUOTE.

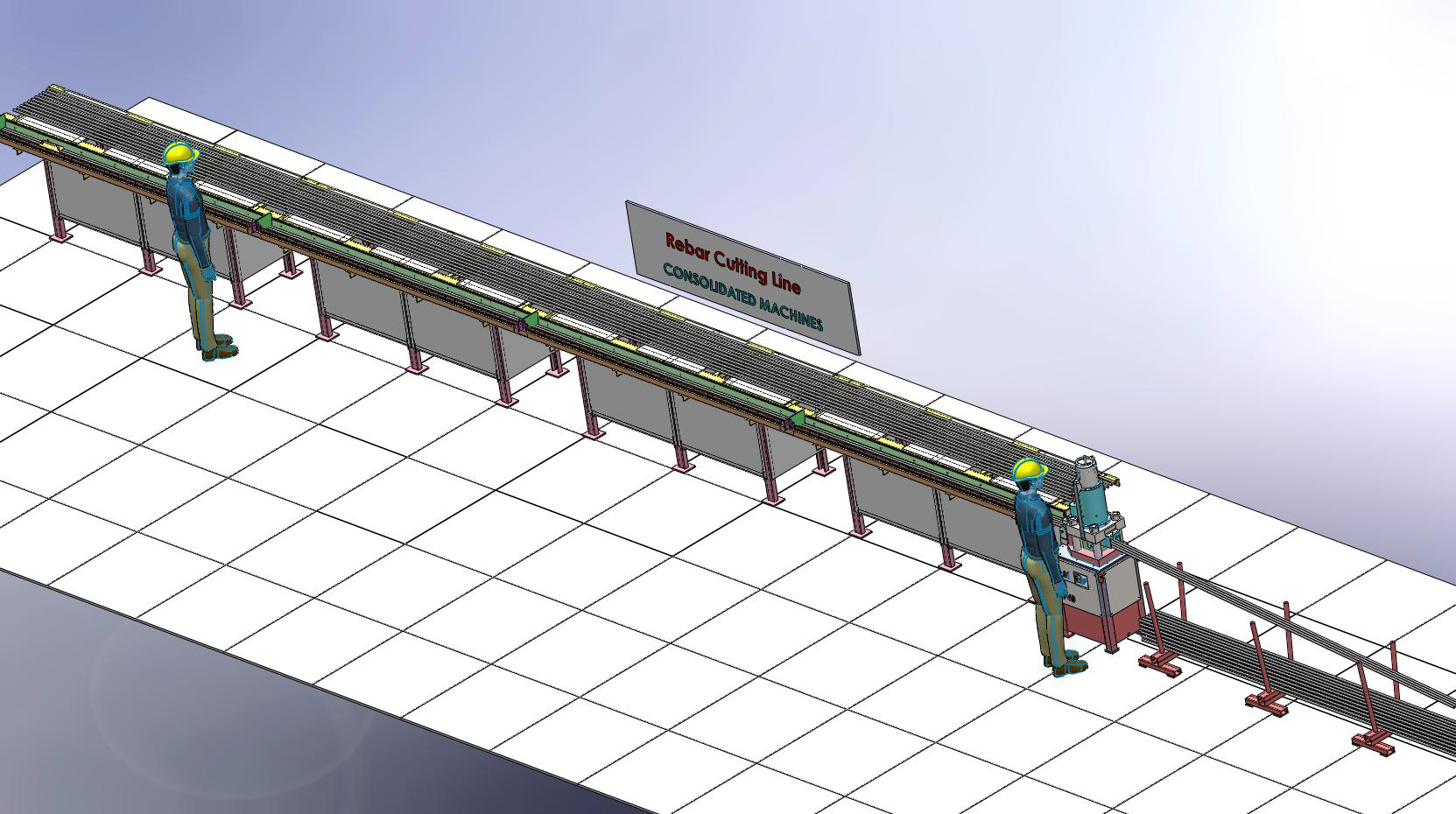

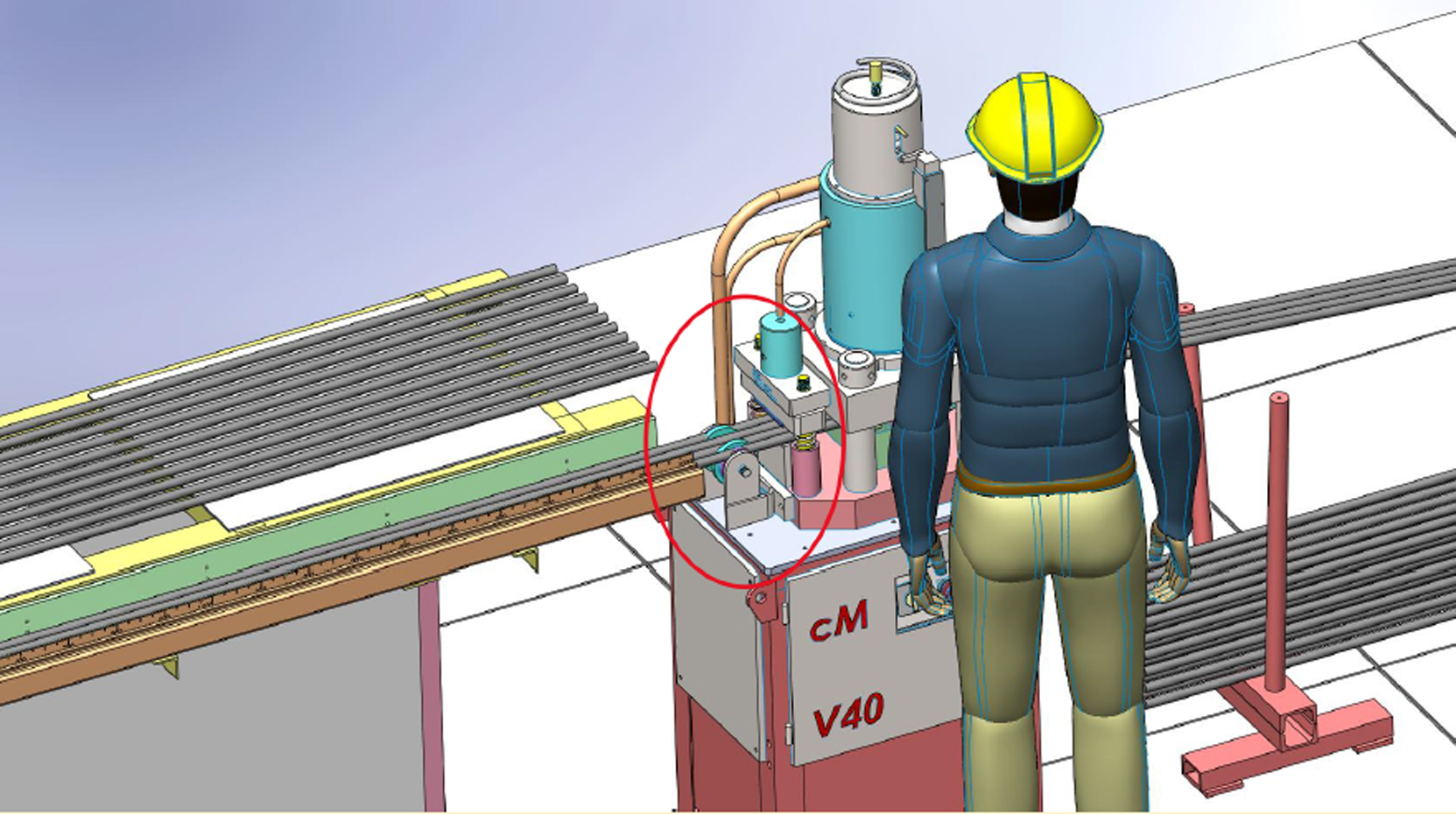

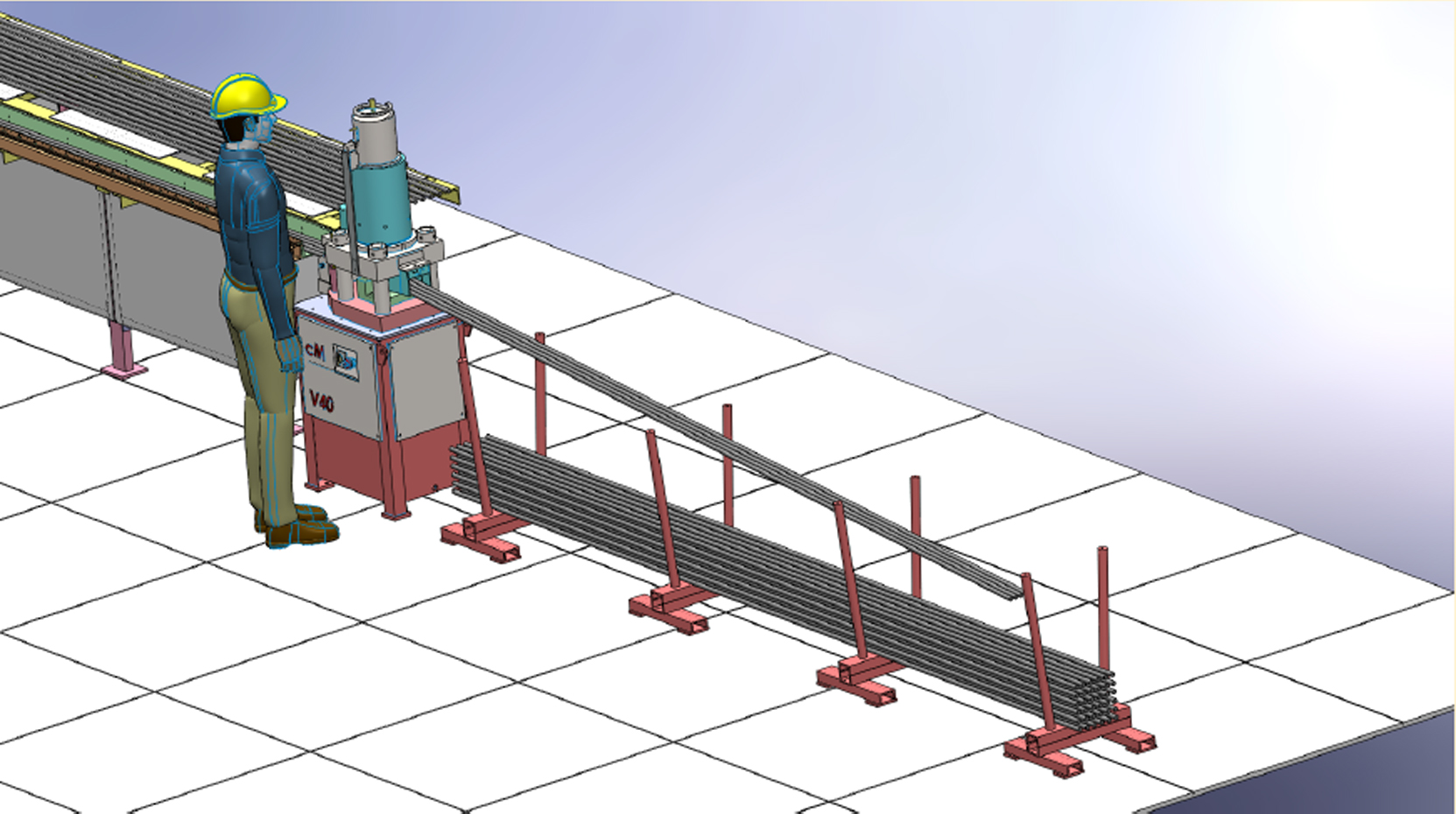

GENERAL ARRANGEMENT VIEW

GENERAL ARRANGEMENT VIEW

REBAR CUTTING LINE MODEL: SLV40 / SLV45

GENERAL FEATURES

✓ Available in Two Models – To Suit Maximum Size TMT Bar METRIC40 GR500 (SLV40) AND METRIC40 GR650 (SLV45) Continuous Processing TMT40GR500 - We Recommend Model SLV45

✓ Heavy Duty Hydraulic Vertical Action Cutting Machine

✓ Arrangement for Bar Feeding with Excellent Length Control Illustrated in Pictures

✓ Production Estimate per Ten Hour Indicative: 40 TONS

✓ Plant Foot Print: 14M X 2.5M (PLUS CUT LENGTH)

✓ Bars in Conveyor Tray Moves Effortless and Properly Guided

✓ Modular Design – Easy to Install or Relocate

CUTTING MACHINE

Electro-Hydraulic

Drive:

Built with Best in Class like Bosch Rexroth / Yuken / Siemens

Cutting Blade Length :

SLV40 100MM SLV45 110MM

Cutting Capacity Metric

Tmt

Grade FE500 / FE550D (Bar Size X No of Bars)

Model SLV40: 40 / 32X1 25X2 20X3 16X5 12X7 10X8 8X10NOS -

Model SLV45: 40 / 32X1 25X2 20X4 16X5 12X8 10X9 8X12NOS

Power Installed:

Standard

Three Phase Ac Motors

Model SLV40 : 5HP (3.8KW)

Model SLV45 : 7.5HP (5.8KW)

CUTTING ACCURACIES

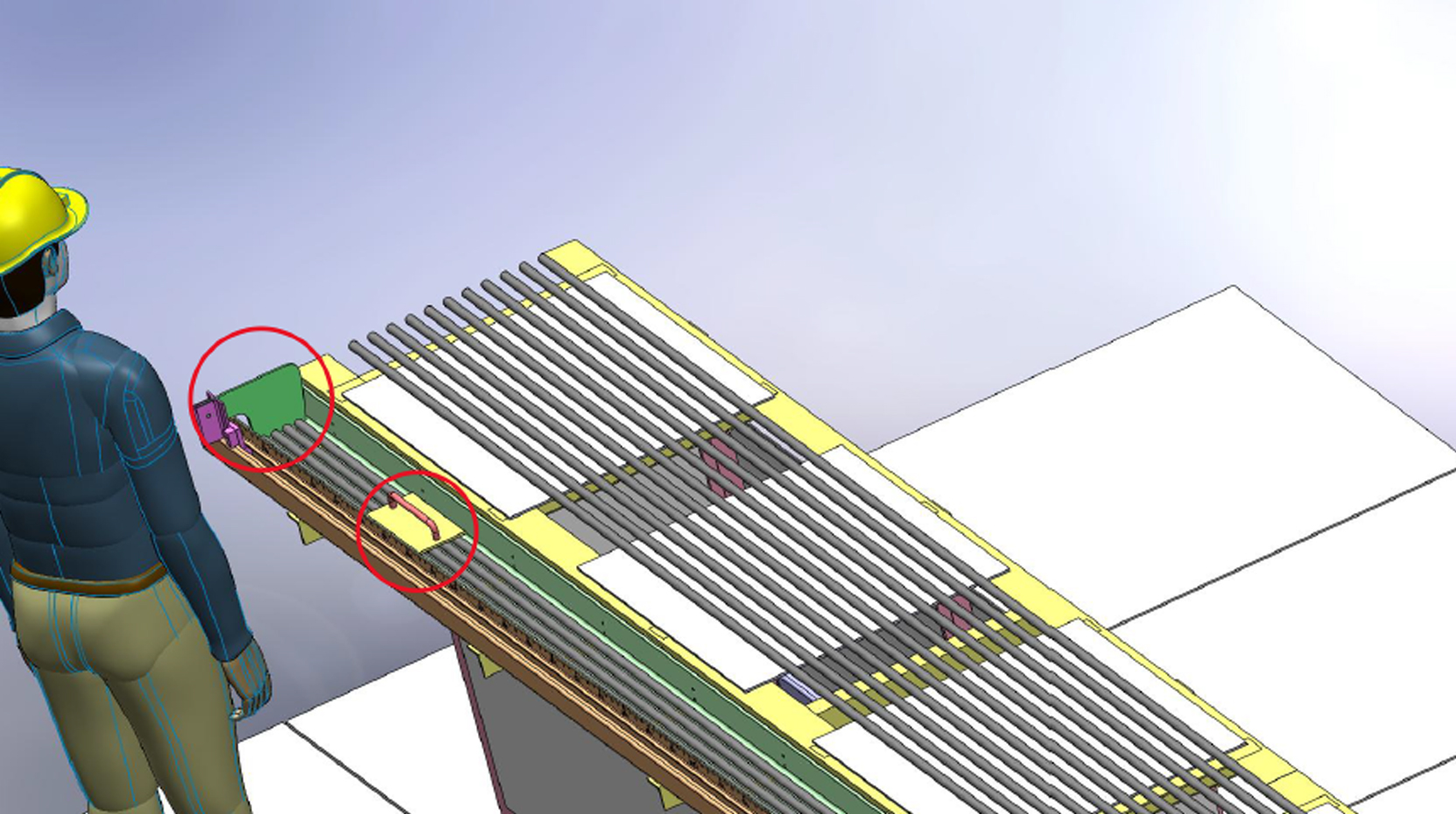

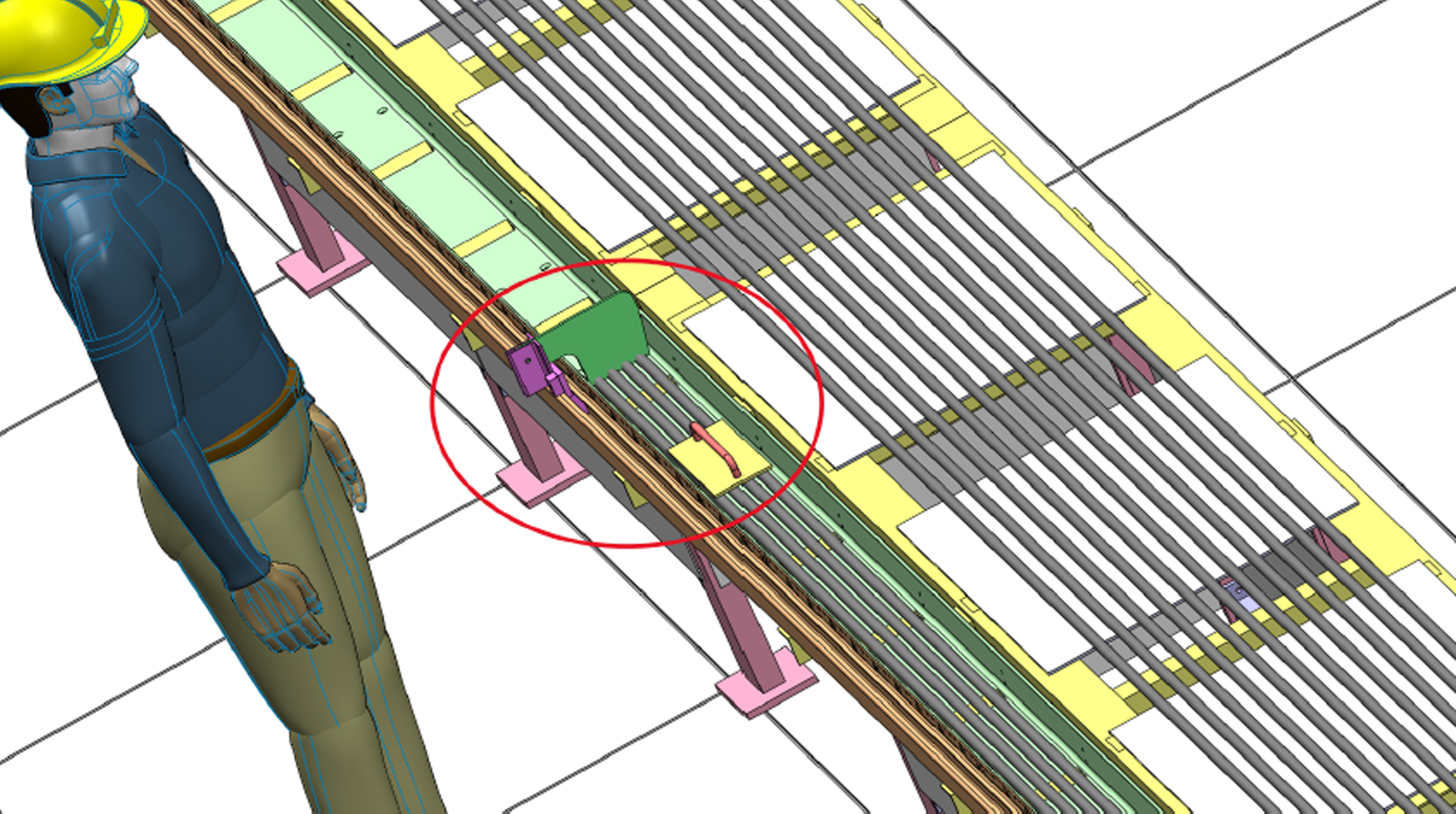

Cutting Accuracy Can Be +/-2mm – See Picture Illustration

BAR SUPPORT SYSTEM

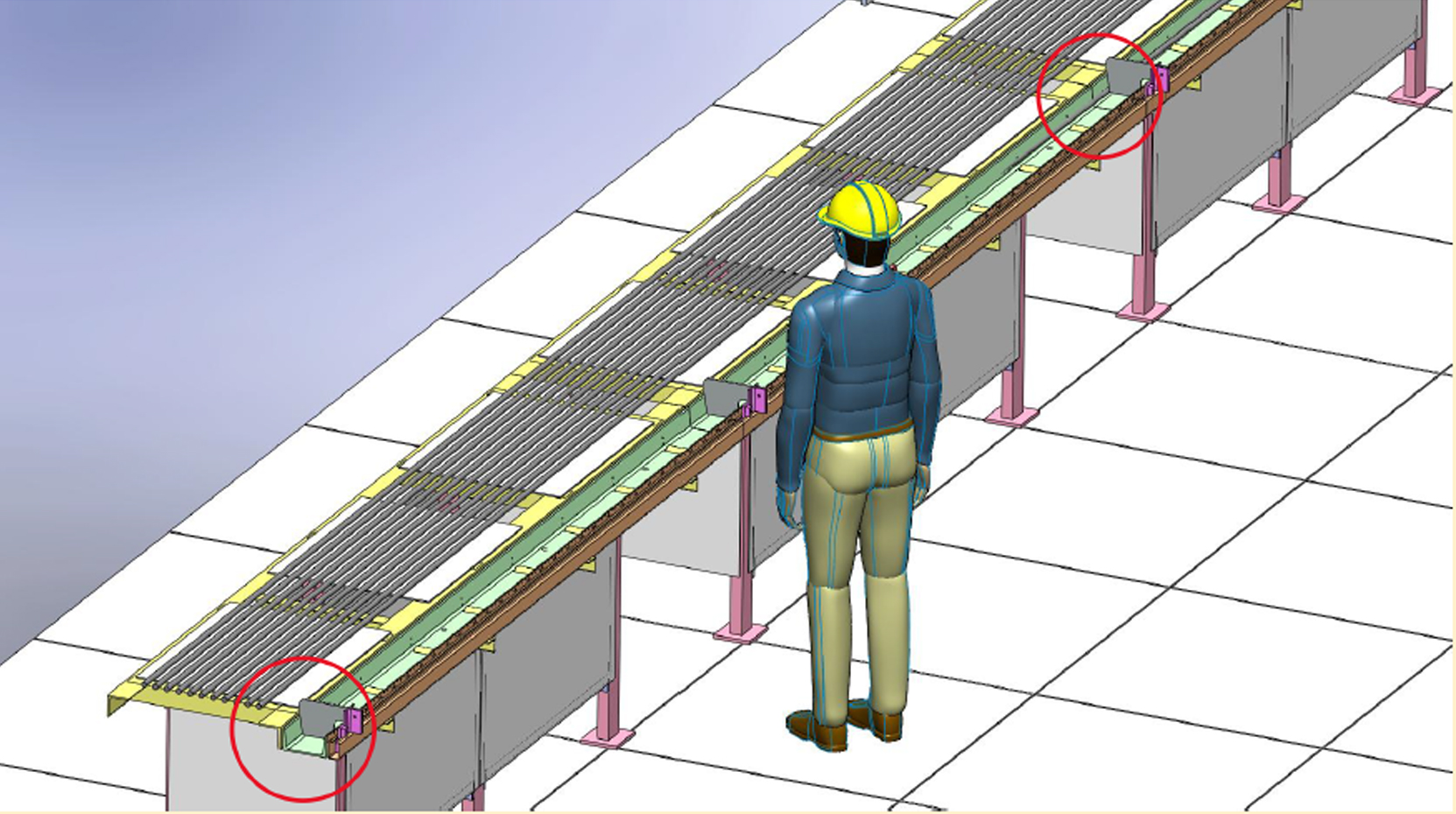

1. Bar Receiving Pedestal Integrated with a Roller Conveyor, Bars to Process Are Dropped-In Rollers Help the Bar to Progress Smooth with Minimal Effort Pedestal Length 12M – Maximum Weight Capable 4T

2. Cut Bars Collecting Elements – Four Numbers – Arranged as Required

MATERIALS AND FINISH

Tooling and Load Bearing Elements of Alloy Steel Toughened, Phosphated for Long Life Panels Powder Coated, Structure Fabrication with Zinc Red-Oxide and Quality Paint Finish

PROCESS ILLUSTION PICTURES

SET STOPPER-FLAGS WITH REFERENCE TO CUT-LENGTH REQUIREMENT

LAST STOPPER-FLAG IS SET FOR REFERENCE CUT – SET AT SAY 11.98M

SET STOPPER-FLAGS WITH REFERENCE TO CUT-LENGTH REQUIREMENT

LAST STOPPER-FLAG IS SET FOR REFERENCE CUT – SET AT SAY 11.98M

DROP THE BARS TO PROCESS IN THE CONVEYOR CHANNEL AND TAKE REFERENCE CUT

HAND HELP PAD TO MOVE BARS

DROP THE BARS TO PROCESS IN THE CONVEYOR CHANNEL AND TAKE REFERENCE CUT

HAND HELP PAD TO MOVE BARS

BARS GLIDE ON ROLLERS – BUTT THE BARS AGAINST THE STOPPER-FLAG

(HAND-HELD PAD TO ASSIST BAR MOVE) OPERATE THE CUT-ACTION

BARS GLIDE ON ROLLERS – BUTT THE BARS AGAINST THE STOPPER-FLAG

(HAND-HELD PAD TO ASSIST BAR MOVE) OPERATE THE CUT-ACTION

BARS ARE GUIDED IN THE MACHINE

BARS ARE AUTOMATICALLY CLAMPED PRIOR TO CUT ACTION

BARS ARE GUIDED IN THE MACHINE

BARS ARE AUTOMATICALLY CLAMPED PRIOR TO CUT ACTION

CUT BARS DROP INTO THE COLLECT BIN AREA

CUT BARS DROP INTO THE COLLECT BIN AREA

DROP US A LINE

Phone:

Hoshang Jhabvala

: +91 98200 77035

Rayomand Jhabvala : +91 98200 79035

Asad Adeni : +91 92465

68775

© Copyright 2020 Consolidated Machines - Designed and Maintained by Upshot Media

Whatsapp Button

Click the "gear" icon to change the layout of the Whatsapp Button. This text will be removed on preview/publish.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.