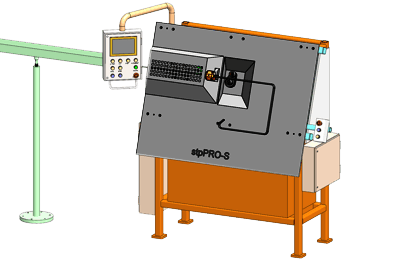

STPPRO - FULLY AUTOMATIC STIRRUP FORMING MACHINE

The stpPRO is stirrup machine operator’s dream machine – USER FRIENDLY - the Full, Straight-Length Stock Bars are loaded onto the machine, the operator feeds in the stirrup specifications (shape and size) and the machine executes the stirrup-forming program continuously in quick succession.

A striking feature of this machine is that multiple specifications of stirrups (different shapes and sizes) can be formed from a single straight-length of rebar thus the entire length of bar is fully utilized with MINIMAL WASTAGE. Programing the machine is pretty simple. Multiple programs can be fed. Stored Programs can be recalled.

The Power train is built with Bosch Rexroth Hydraulics and controlled by a reliable PLC. Compared to machines with servo drives, it is easy to maintain and economically priced.

This machine is capable of bar handling up to size 16 and capable of bending in both directions.

For Detail Specs Download Catalogue from the link below.