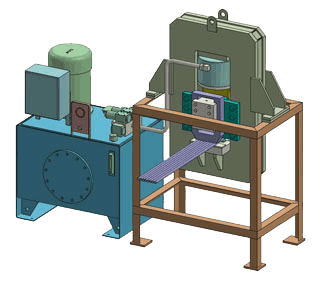

CUTPRO32 - AUTOMATIC BAR CUTTING MACHINE

Introduced in 2005, the Automatic Rebar Cutter Model cutPRO32 from Consolidated Machines (CM) is a machine designed on cutting-edge designing software, manufactured using computer-aided methods and improved over the years based on feedback of end-users. cutPRO32 is a sturdy robust machine, filled with all the hallmark characteristics of every machine from Consolidated Machines (CM) -- a high degree of cutting accuracy, high on safety, reliability, high productivity, easy to maintain and a long life cycle. Highly recommended for the following users:

✓ Large civil engineering project sites requiring huge quantities of cut-to-size steel in quick time

✓ TMT Bar Mills supplying value-added products (cut-to-size reinforcing steel)

✓ Cut & Bend rebar plants

For Detail Specs Download Catalogue from the link below.