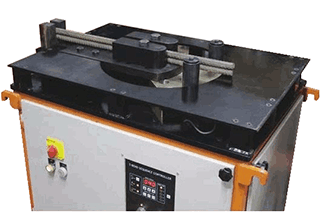

B/BA SERIES - BAR BENDING MACHINE

Consolidated Machines (CM) Series B and BA are Identical bar bending Machines, except for the PLC Controls that are fitted to the BA-Series.

Project Managers of modern high-rise concrete structure and critical infrastructure projects follow a precisely-defined Bar Bending Schedule (BBS). Accuracy in construction is the key to the structure’s long-life. The BA-Series of bar benders from Consolidated Machines (CM) perfectly match the site’s exacting specifications of accuracy. The highly-reliable Programmable Logic Controller (PLC) fitted on the BA-Series of Bar Benders delivers the steel with a Bending Angle to a precision of one degree. The automation in the BA-Series of benders enables the machine operator to pre-set successive bending angles and continuously execute the bending operations. EXTREMELY HANDY when large quantities of steel has to be bent multiple times at differing angles!! This Feature also plays an important role when our Bar Bending Machines are used to Form Stirrup Rings.

Bending Speed Control – an Optional Feature

Our Hydraulic Drive Bar Benders are fitted with Bending Speed Controls, which is an ESSENTIAL Requirement when Bending PU (Epoxy) Coated Bars

For Detail Specs Download Catalogue from the link below.