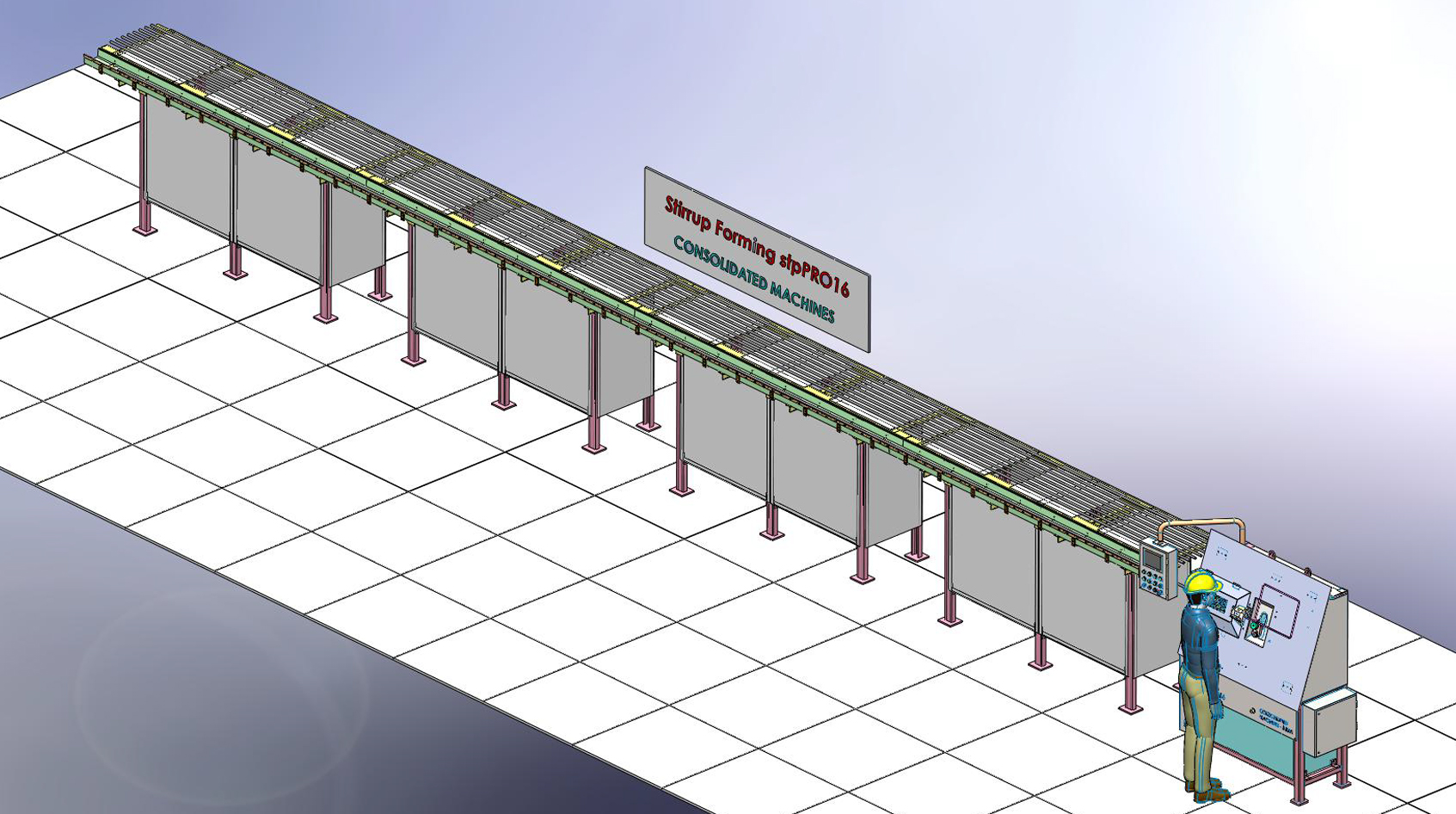

Automatic Stirrup Line Model STPPRO16

General Arrangement View

General Arrangement View

General Features

Capable Maximum Size TMT Bar 16 GR FE500 / 550D

Electro-Hydraulic System with PLC Controls

Bar Support Pedestal with Conveyor Tray to Assist Bar Feeding

Production Estimate per Ten Hour Indicative: 2 / 10 TONS

Plant Foot Print: 14M X 2.5M

Full Automatic Function

Modular Design - Easy to Install / Relocate

Machine - Automatic Stirrup Bender STPPRO16

Electro-Hydraulic Drive

Built with Best in Class like Bosch Rexroth / Yuken / Siemens

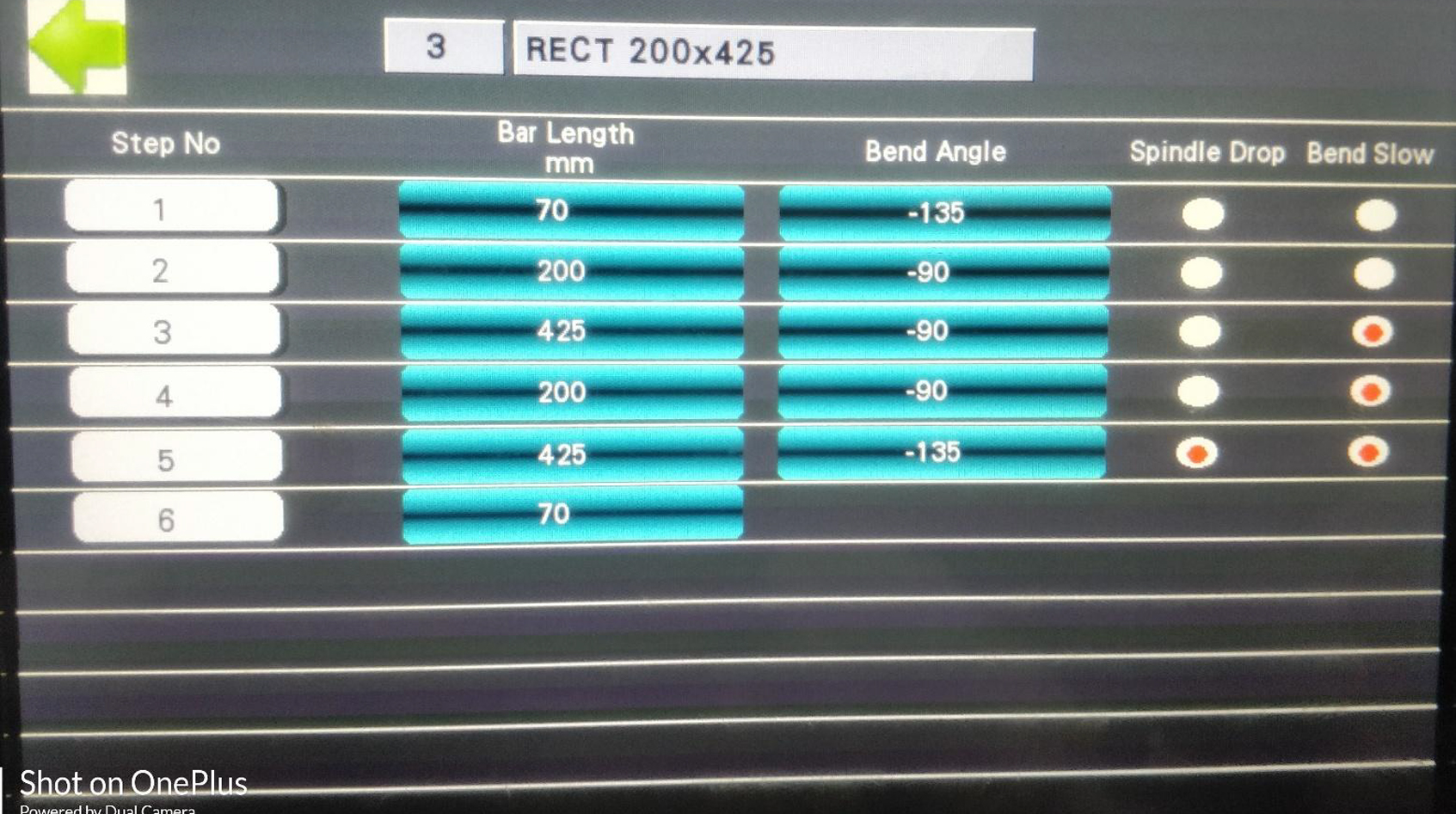

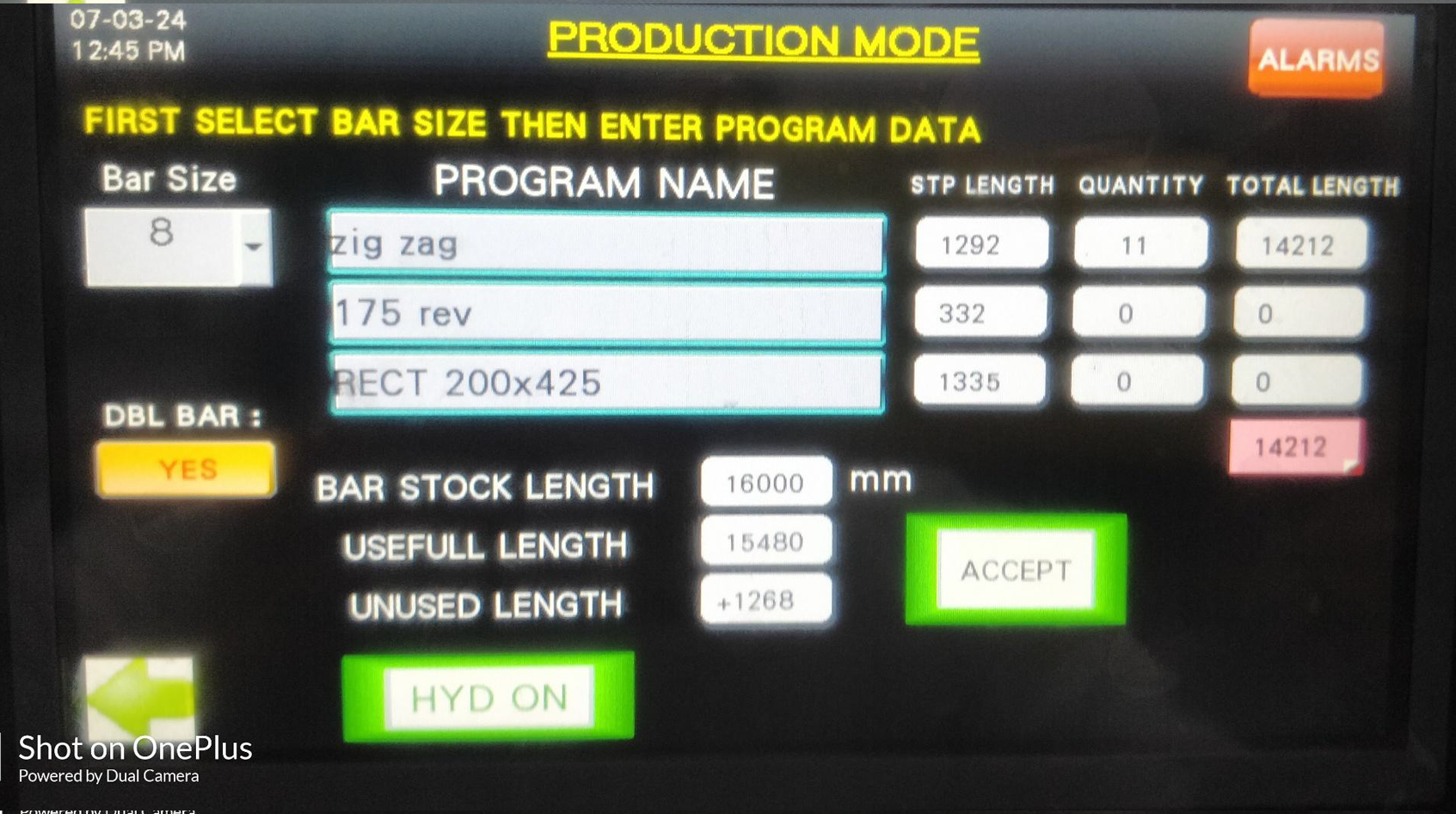

PLC Control System - A 12M Stock Bar May Be Formed in Various Stirrup Shapes. Such Data Is Stored as a Program. A Program Is Recalled and Machine Set in Motion

For Convenience or Optimize Bar Wastage – We Can Run a Cycle Where

The 12M Stock Bar Can Be Formed in Different Shapes with Defined

Quantiles.

For Convenience or Optimize Bar Wastage – We Can Run a Cycle Where

The 12M Stock Bar Can Be Formed in Different Shapes with Defined

Quantiles.

Bending Capable – Metric TMT Size 16/12/10 X 1 No. Size 8 X 2Nos Bend Tooling to Suit Inner Bend Radius Near 2XD

Protective Cover Provided on Feeder Interlocked with Run Mode

Compact Electro-Hydraulic Drive Is Integrated in the Machine

Power Installed: Standard Three Phase AC Motors 5HP (3.8KW)

Bending Speed Near 40RPM (Variable Control) – Ideal for Large Shapes

Pull Speed Near 600 MM/SEC

Performance Accuracies

Bending Accuracy +/- 1.5 DEG or Better

Length Accuracy +/- 2MM per Meter Length or Better

CAUTION - Bending Accuracy Repeatibility Also Depends on Bar Material Elasticity

Caution Notes

In General in Any Automatic Process, the Material Consistency Is Important In This Case the Bar Quality Matters for a Smooth Operation Mill Bars Good Straightness – Uniform Dimensions and Roundness – Bar Ribs Uniform and Linear.

If the Uniformity Is Not so Good, Bars When Pulled Tend to Rotate Which Distorts the Plane of the Product. However, Operators Mild Support Can Control This Issue Effectively.

Also the Machine Has the Option to Engage “semi-Auto Mode” Where the Plane of the Forming Product Can Be Corrected before the following “bend Action”

Bar Support System

1. Bar Receiving Pedestal Integrated with a Roller Conveyor, Bars to Process Are Dropped-In. Rollers Help the Bar to Progress Smoothly Pedestal Length 12m – Maximum Weight Capable 4t Distributed

Materials and Finish

Tooling and Load Bearing Elements of Alloy Steel Toughened, Phosphate Finish Panels Powder Coated, Structure Fabrication with Zinc Red-Oxide and Quality Paint Finish