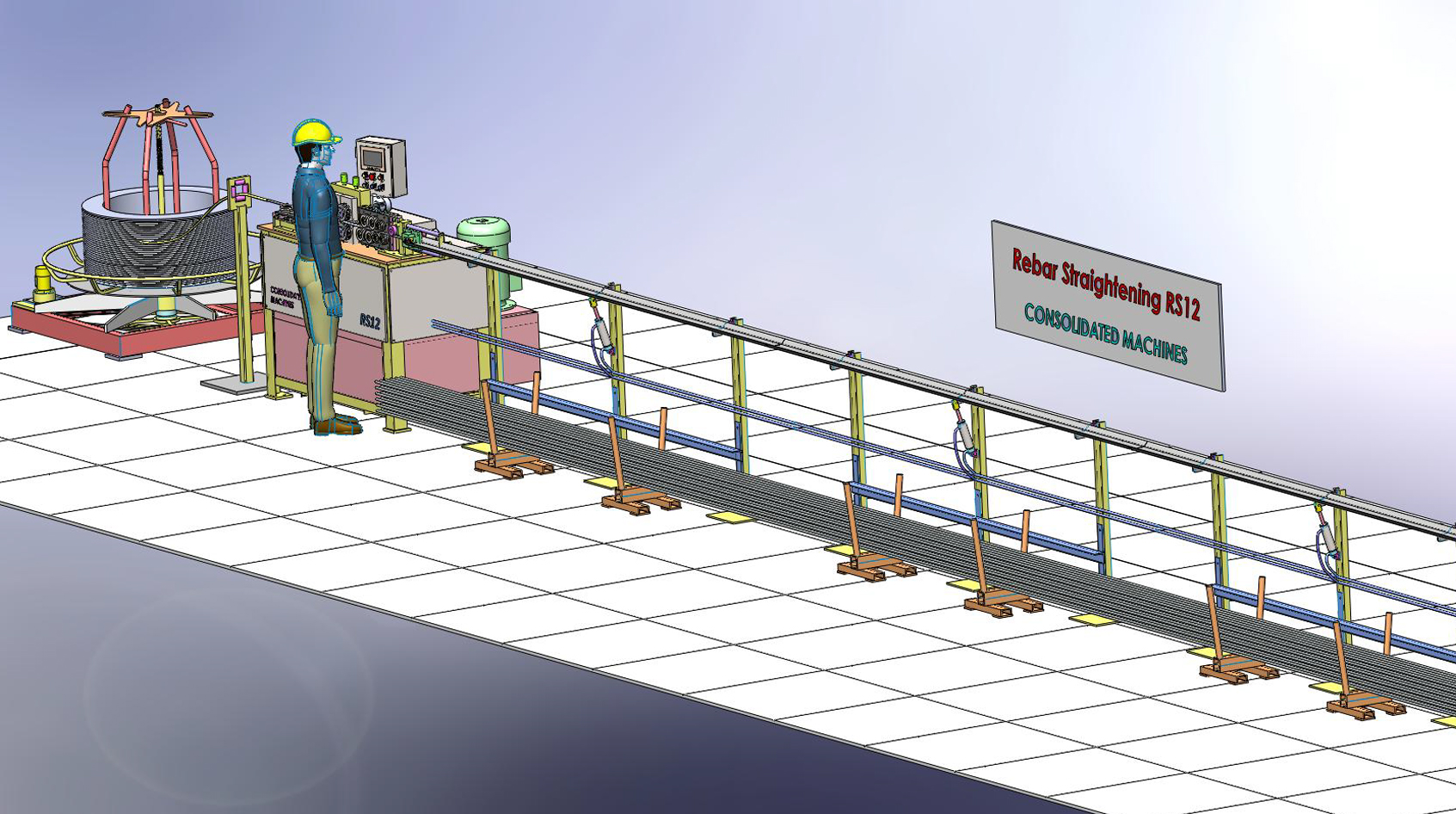

Rebar Straightening Line - RS12

General Arrangement with 12m Collecting System

General Arrangement with 12m Collecting System

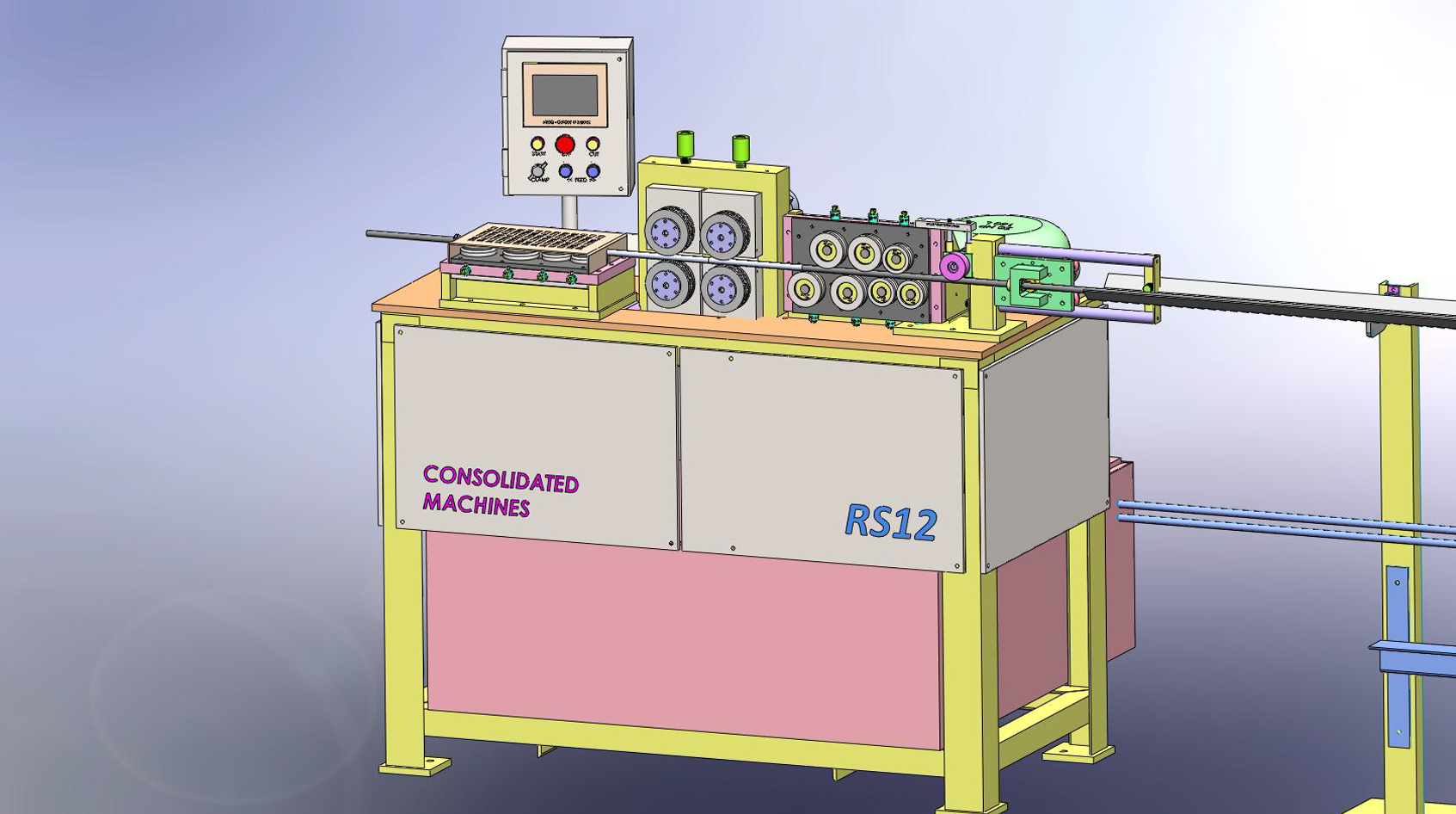

General Features

Commonly Used by Rebar Distributors to Convert Coil Form to Straightened Product

Bar Straightening in Two Planes – Progressive with Multiple Roller Arrangement

Coil Dispenser Unit – Details Provided

Bar Collecting System – Modular Construction

Plant Foot Print: 16M X 2.5M

Modular Construction – Easy to Install or Relocate

Straightening Machine

Specifications

Bar Sizes Capable : TMT Metric Size 8 / 10 / 12 (Usa Equivalent #2 / #3 / #4)

Straightening Speed: 48 Meters per Minute

Power Installed : 20 HP (15.6 KW) – AC ELECTRIC MOTORS

Electro-Hydraulic Drive Built with Best-In-Class Elements like Bosch Rexroth / Yuken / Siemens

PLC Controls : Omron / ABB / DELTA

Coil Dispenser:

Powered System to Synchronize with Machine Speed - To Ensure Smooth Running

Accepts Coil Sizes : Minimum ID 650 MM - Maximum OD 1200 MM - Maximum Height Maximum Coil Weight 2500 KGS

Bar Receiving System:

Four Meter Modules – With Bar Collecting Bins

Accepts Coil Sizes : Minimum ID 650 MM - Maximum OD 1200 MM - Maximum Height Maximum Coil Weight 2500 KGS

Materials and Finish:

Tooling and Load Bearing Elements of Alloy Steel Toughened, Phosphate Finish Panels Powder Coated, Structure Fabrication with Zinc Red-Oxide and Quality Paint Finish

DROP US A LINE

Phone:

Hoshang Jhabvala

: +91 98200 77035

Rayomand Jhabvala : +91 98200 79035

Asad Adeni : +91 92465

68775

© Copyright 2020 Consolidated Machines - Designed and Maintained by Upshot Media

Whatsapp Button

Click the "gear" icon to change the layout of the Whatsapp Button. This text will be removed on preview/publish.

Floating Social Menu and Ribbons

Click the "gear" icon to change the layout of the social bar. This text will be removed on preview/publish.